02-26-2021 |

02-26-2021 |  Hits:1078

Hits:1078

With the development of automobile industry, the vibration produced in the process of automobile driving has become a major obstacle to the development of automobile. The vibration generated in the process of driving will seriously reduce the comfort, stability and safety of the car, not only reduce people's enjoyment when they ride the car, but also shorten the service life of auto parts. Therefore, in the case of people's increasing requirements for automobile comfort and safety, the importance of automobile shock absorber is becoming more and more prominent. The shock absorber with production performance and quality meeting the high-speed operation of automobile has become an urgent problem in the automotive field.

1、 What is shock absorber

Shock absorber is a kind of equipment used to restrain the shock and road impact when spring rebounds after shock absorption, which is widely used in the automotive industry. In order to make the vibration of the frame and body attenuate rapidly, and improve the ride comfort of the car, the car suspension system is generally equipped with shock absorber. When passing through the uneven road, although the shock absorption spring can filter the vibration of the road, the spring itself will have reciprocating motion, and the shock absorber is used to suppress this spring jump.

2、 Classification and working principle of shock absorber

From the angle of producing damping materials, there are two kinds of shock absorbers: hydraulic shock absorber and pneumatic shock absorber. In addition, there is a kind of shock absorber with variable damping.

① Hydraulic type

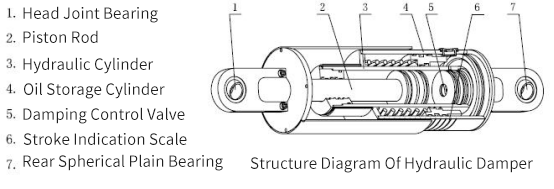

Hydraulic shock absorber is widely used in automobile suspension system. The principle is that when the frame and axle do reciprocating relative motion and the piston moves back and forth in the shock absorber cylinder, the oil in the shock absorber shell will repeatedly flow into another cavity through some narrow pores. At this time, the friction between the liquid and the inner wall and the internal friction of the liquid molecules form the damping force to the vibration.

② Inflatable

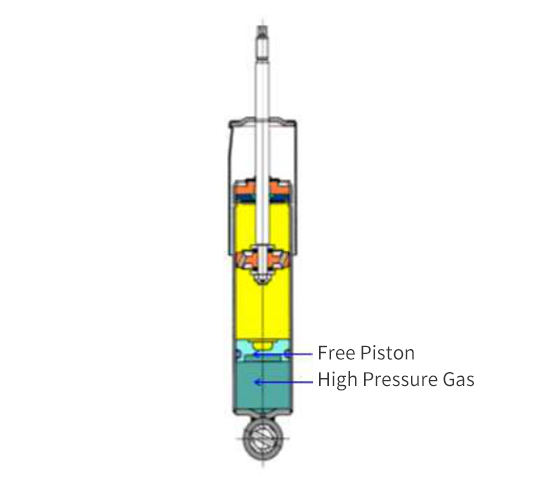

Inflatable shock absorber is a new type of shock absorber developed since 1960s. The structure features that a floating piston is installed at the lower part of the cylinder barrel, and a closed gas chamber formed by the floating piston and one end of the cylinder barrel is filled with high-pressure nitrogen. A large section O-ring is installed on the floating piston, which completely separates oil from gas. The working piston is equipped with a compression valve and an extension valve which change the cross-sectional area of the passage according to the movement speed. When the wheel jumps up and down, the working piston of the shock absorber moves back and forth in the oil, causing the oil pressure difference between the upper chamber and the lower chamber of the working piston, and the pressure oil pushes the compression valve and the extension valve to flow back and forth. Because the valve has a large damping force on the pressure oil, the vibration is attenuated.

③ Variable damping shock absorber

In addition to the two shock absorbers mentioned above, there are also shock absorbers with adjustable resistance. It can change the size of the orifice by external operation. Recently, the electronic control shock absorber is used as the standard equipment in the automobile. The running state is detected by the sensor, and the best damping force is calculated by the computer, so that the damping force adjusting mechanism on the shock absorber can work automatically.

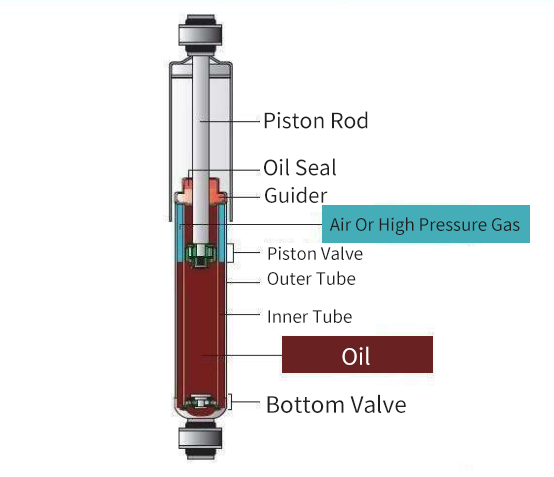

The structure of the shock absorber is that the piston rod with piston is inserted into the cylinder, and the cylinder is filled with oil. There is an orifice on the piston, so that the oil in the two parts separated by the piston can supplement each other. Damping is produced when viscous oil passes through the orifice. The smaller the orifice is, the greater the damping force is. The greater the viscosity of oil is, the greater the damping force is. If the size of the orifice remains unchanged, when the shock absorber works at a high speed, excessive damping will affect the shock absorption. Therefore, a disc-shaped leaf spring valve is set at the outlet of the orifice. When the pressure increases, the valve is jacked open, the orifice opening increases and the damping decreases. Because the piston moves in two directions, leaf spring valves are installed on both sides of the piston, which are called compression valve and extension valve respectively. According to its structure, shock absorber can be divided into single tube and double tube.

① Double barrel

Double cylinder shock absorber means that the shock absorber has two inner and outer cylinders. The piston moves in the inner cylinder. Due to the entry and extraction of the piston rod, the volume of oil in the inner cylinder increases and shrinks. Therefore, the oil balance in the inner cylinder should be maintained by exchanging with the outer cylinder. Therefore, there should be four valves in the double cylinder shock absorber, that is, in addition to the two throttle valves on the piston mentioned above, there are also flow-through valves and compensation valves installed between the inner and outer cylinders to complete the exchange function.

Double tube shock absorber

② Single barrel

Compared with the double cylinder shock absorber, the single cylinder shock absorber has simple structure and reduces a set of valve system. It is equipped with a floating piston in the lower part of the cylinder (the so-called floating means that there is no piston rod to control its movement), and forms a closed gas chamber under the floating piston, which is filled with high-pressure nitrogen. The change of the liquid level caused by the oil flowing in and out of the piston rod mentioned above is automatically adapted by the floating of the floating piston.

Single cylinder shock absorber

3、 Fatigue performance test of shock absorber

Shock absorber as a vulnerable part in the process of automobile use, its working performance will directly affect the stability of automobile driving and the service life of other parts. If the shock absorber does not meet the use standard, it will affect the brake, cause tire wear and other problems, and even make the automobile control failure, resulting in safety accidents. Due to the long-term working state and wear of shock absorber in the process of vehicle driving, the service life of shock absorber products is closely related to its anti fatigue performance, which is also an important part of shock absorber product quality control. The shock absorber double excitation fatigue testing machine developed by wance is a special testing machine for automobile shock absorber fatigue test. It has four working positions, and can carry out axial fatigue test for four or two shock absorbers at the same time.

BV Scientific shock absorber double excitation fatigue testing machine can carry out axial fatigue test and lateral load on automobile shock absorber at the same time. It adopts German imported oil cylinder with reliable sealing performance, low damping and long service life. It can load the upper and lower oil cylinders coordinately, or one oil cylinder can be loaded alone, and the other oil cylinder can be stationary. The supporting test software interface displays the real-time force and damping The peak and trough of displacement, including sine wave, triangle wave, square wave, trapezoidal wave, external input wave, etc. The machine can also monitor the surface temperature of the shock absorber in real time. If the temperature is too high, spray cooling can be implemented. During the cooling period, the oil cylinder can be set to three states: automatically stop loading, reduce the loading speed, and keep the original speed unchanged. According to the user's demand, spray cooling can be changed to blowing cooling.

4、 Use and maintenance of shock absorber

The service life of shock absorber is not only related to its anti fatigue performance, but also related to the use and maintenance methods. Therefore, the following points should be paid attention to in the daily driving process:

1. If the road surface is poor, such as ditch and ridge, it needs to slow down. Especially when the road condition is poor, the piston of the shock absorber may bottom out and cause damage to the shock absorber if it passes through the potholes quickly.

2. Avoid placing heavy objects in the trunk for a long time. Generally, the four-wheel shock absorbers have been adjusted to the best condition. When heavy goods are placed in the trunk for a long time, it will cause heavy pressure on the rear wheel shock absorption and increase the force on the oil seal, thus increasing the possibility of oil leakage from the shock absorber.

3. Avoid tilting the vehicle for a long time. Some cities or residential parking space tension, in order to make more space for the road, most car owners will choose one side of the wheel to ride on the curb, so that the vehicle side high side low, uneven stress will also cause shock absorber damage.

4. Check the shock absorber regularly. In general, the shock absorber should be inspected every 20000 km to check whether the shock absorber has oil leakage, failure and other problems. During the inspection, press down the bumper and release it. If the car jumps 2-3 times, it means that the shock absorber works well.